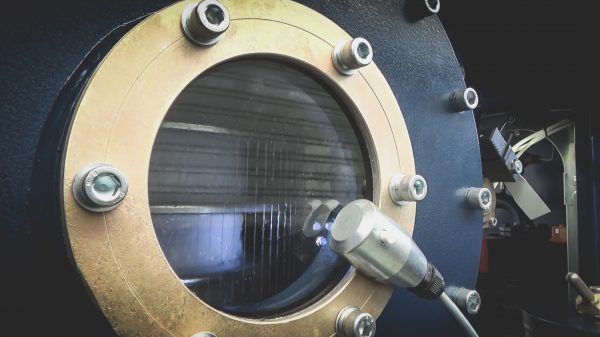

September 17, GlobeCore engineering team started up the CMM-2,2 oil purification unit in Foligno (Umbria region), Italy.

The unit’s tests were carried out on site of a large Italian locomotive service and production facility.

They use silicone oil as a dielectric and lubricant for their equipment.

Recently this type of oil has become increasingly popular in light, heavy, automotive and other industries. Silicone oil has excellent dielectric properties. Due to the predominance of silicon atoms in the composition of this oil, it is not flammable, in contrast to hydrocarbon analogues.

Italian colleagues provided two oil samples (contaminated oil and clean oil) for purification. When working with different oils, it is important to undertake several preparatory steps. Namely:

- rinse the unit (to avoid mixing mineral and silicone oils);

- replace the filter elements in the filters;

- replace the filter activators in the vacuum column.

We are very pleased that the representative of the company “LubeTeam Hydraulic” Antonio Pisaniello, who was present at the start-up, appreciated GlobeCore equipment. Mr. Pisaniello said: “We were present at the commissioning of the equipment for filtration of silicone oil for railway locomotive 402B of Ansaldo / Hitachi to in Foligno. The start up was successful. I am satisfied with the work done. I thank you and until the next time”

We also want to thank our Italian colleagues for providing us an opportunity to gain new experience.