GlobeCore Statement on the COVID-19 Coronavirus Infection Pandemic

GlobeCore closely monitors the situation around the world due to the outbreak of the COVID-19 coronavirus infection. Under the circumstances, we are doing all we can to protect our employees.

We also consider it our duty to make a contribution to the protection of the global community. Millions of people are quarantined, and they must be provided with comfortable living conditions. Power generation, distribution and transmission facilities, including transformers, must not stop even for a minute, and must continue to generate electric power to fully satisfy the demand. Therefore, our employees continue to provide online technical support for high quality servicing of such facilities. The modern communication technologies allow us to do so without any risk to the health of both the GlobeCore specialists and that of our partners, which is our main priority.

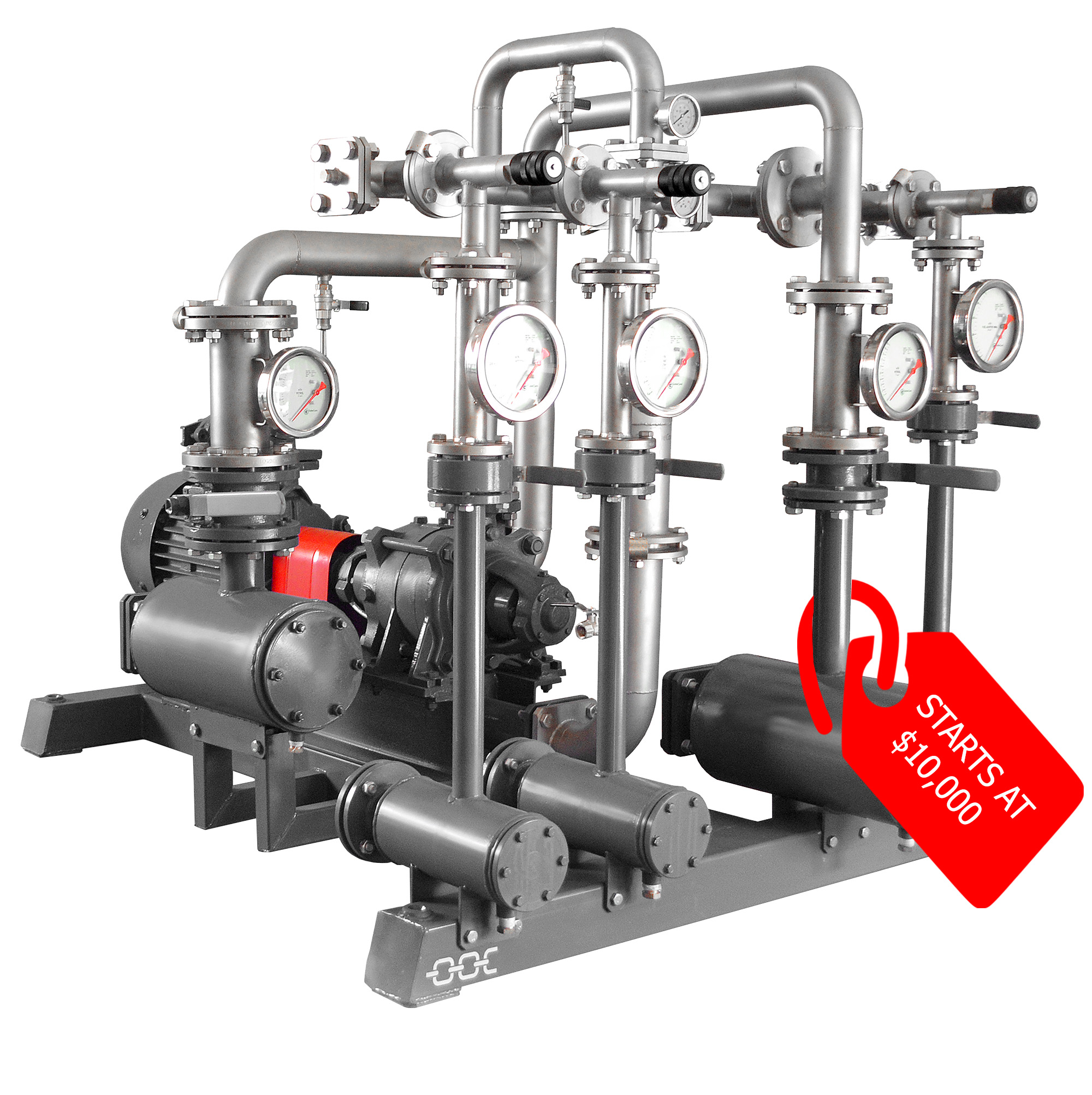

The pandemic can only be stopped by a common effort. However, it is difficult to do so without a sufficient supply of antiseptic and disinfectant materials. To increase the production, GlobeCore is ready to supply the USB blending units on a very short notice. These machines are based on modern continuous stream blending of liquid ingredients, which allows to either increase the production rates of the existing facilities or quickly commission new production lines.

We will put a stop to COVID-19 together!

Products

News & Publication

-

Industrial Disinfectant Making Machine

4.6.2020

Antiseptic production as a business The strains of microorganisms... Read More -

GlobeCore’s Invitation to IEEE PES T&D 2020

3.12.2020

GlobeCore would like to invite all our partners to... Read More -

GlobeCore extends invitation to the International Construction & Utility Equipment Exposition-2019

GlobeCore extends invitation to the International Construction & Utility Equipment Exposition-2019

8.12.2019

GlobeCore extends invitation to the International Construction & Utility Equipment Exposition-20198.12.2019

GlobeCore invites all businesses and parties interested in the... Read More -

GlobeCore Invitation to Transformador LatAm 360

8.5.2019

Transformador LatAm 360 symposium, dedicated to transformer lifecycle, will... Read More

-

GlobeCore participated in the largest electrical industry exhibition in Latin America

12.20.2017

November 29 to December 1, GlobeCore promoted its equipment... Read More -

GlobeCore Presentation in the Philippines

12.14.2017

Frank May of GlobeCore visited the Philippines on 4-7... Read More -

GlobeCore Regeneration Equipment Presentation in Qatar

12.11.2017

GlobeCore representatives visited Doha, Qatar, to showcase the company’s... Read More -

A seminar on purification and regeneration of industrial oils will be held in Costa Rica on 4 May

A seminar on purification and regeneration of industrial oils will be held in Costa Rica on 4 May

11.28.2017

A seminar on purification and regeneration of industrial oils will be held in Costa Rica on 4 May11.28.2017

Dear customers and partners! GlobeCore GmbH invites you to... Read More

-

Vacuum Oil filter Machine

3.27.2018

Oil degradation is a wide-spread problem in industries using... Read More -

Environmental effects of transformer oil recycling systems

12.14.2017

transformer oil recycling Transformer oil is an essential component... Read More -

Oil Purification Methods GlobeCore

10.15.2017

Classic Ways of Used Oil Purification In today’s industrial... Read More -

How To Manage Waste Oil Purification?

10.15.2017

Waste oil is considered to be hazardous waste since... Read More

Globecore video chanel

About GlobeCore

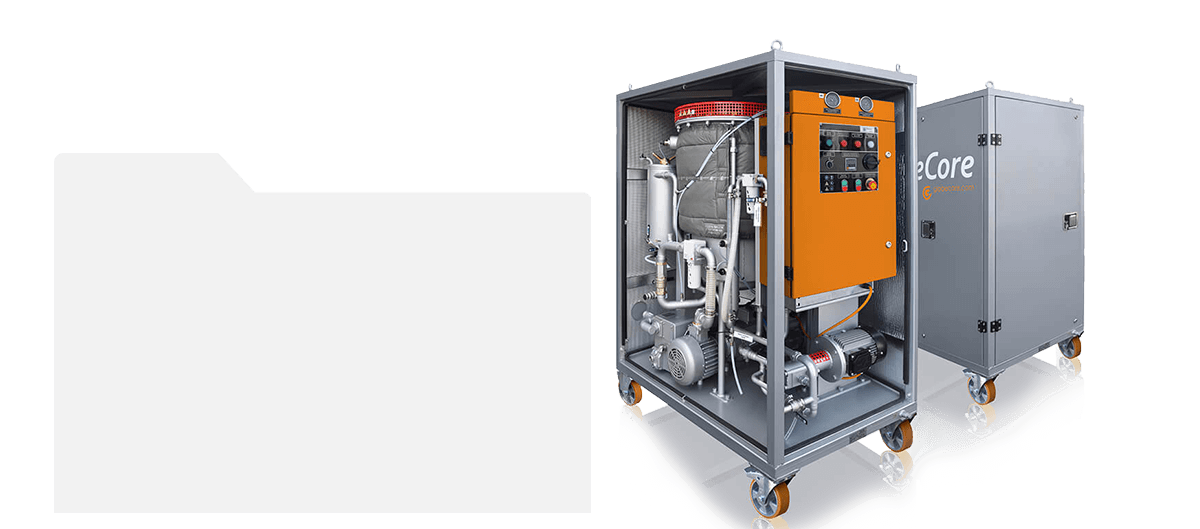

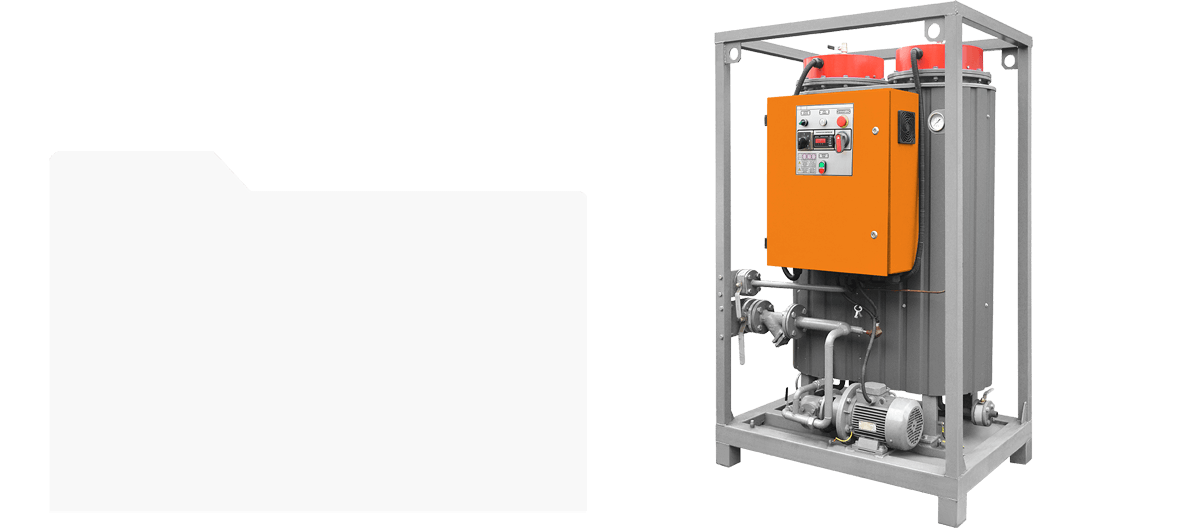

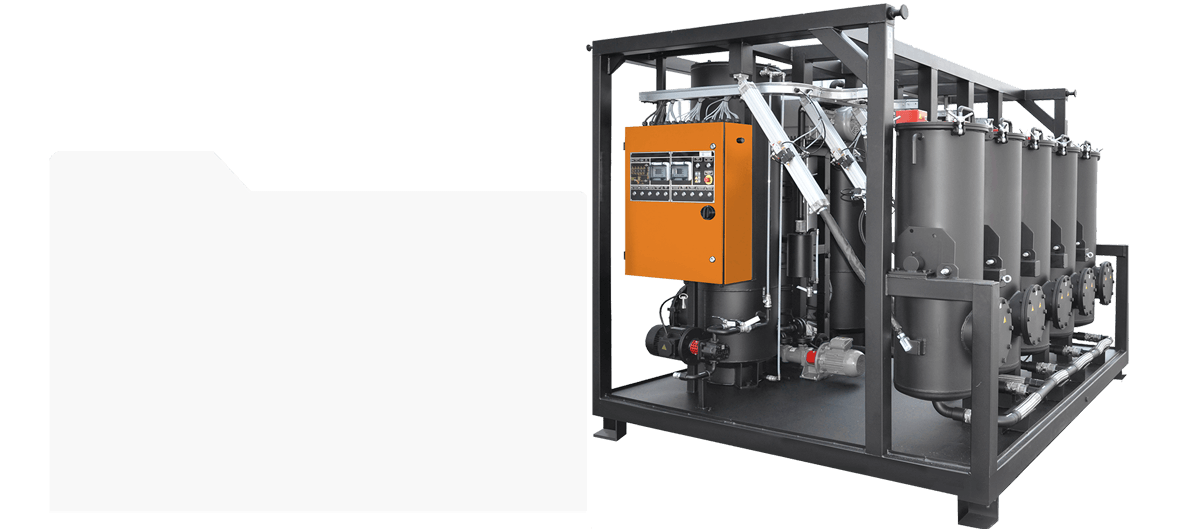

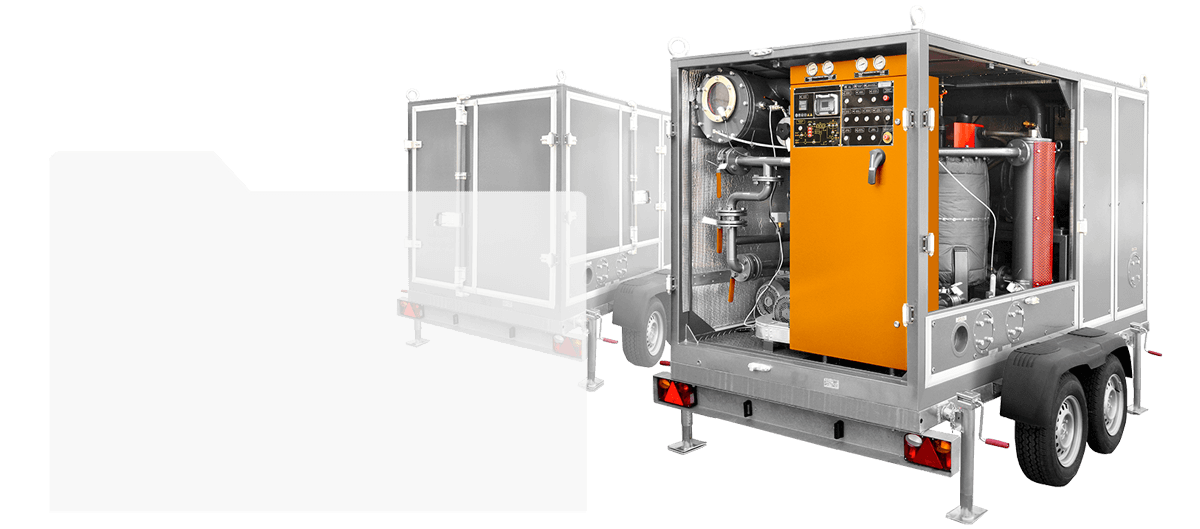

GlobeCore is one of the world leaders in industrial manufacturing. Products of GlobeCore are used in transformer oil purification and degassing, insulation oil filtration, oil reclamation, and power transformer vacuuming.

The head office and production facilities are located in Poltava, Ukraine. Our systems have been supplied to and are successfully operated in more than 100 countries. A global network of over 100 dealers supports worldwide sales and services.

GlobeCore has established representative offices in the United States, South Africa, and the United Arab Emirates to extend reach and improve efficiency. We actively expand production and sales territories, develop our infrastructure, and introduce new additional services.

GlobeCore is a member of the American Wind Energy Association. The production facility is equipped in compliance with international industry standards: it features robotic plasma metal cutters, automated welding systems, and modern PLC-controlled machinery.

The engineering staff systematically develops new oil purification equipment and improves existing product lines. GlobeCore manufactures hundreds of units annually, with each product thoroughly tested at the company’s own testing facility.

Hundreds of positive letters and comments from our clients confirm that we are moving in the right direction. Over the years, we have established numerous contacts and created a wide network of returning customers. And we are not stopping. GlobeCore is open for new opportunities and invites everyone to visit our facility in Poltava.