Antiseptic production as a business

The strains of microorganisms constantly mutate. New viruses and bacteria appear, and it is better to prevent the disease than try to cure it later. This is why the market for hand and surface treatment antiseptics will grow, remaining a promising business. The use of antiseptics in the developing countries has not yet become commonplace, which makes for viable export opportunities.

Hand and surface treatment antiseptic formula

The simplicity of the formula is another advantage of household antiseptic production. Some of the basic components are alcohol (at least 60%), a moisturizer and a scent, which covers the unpleasant smell of alcohol.

These components must be thoroughly blended, making blending equipment the centerpiece of every hand and surface antiseptic production line.

Blending equipment for antiseptic production

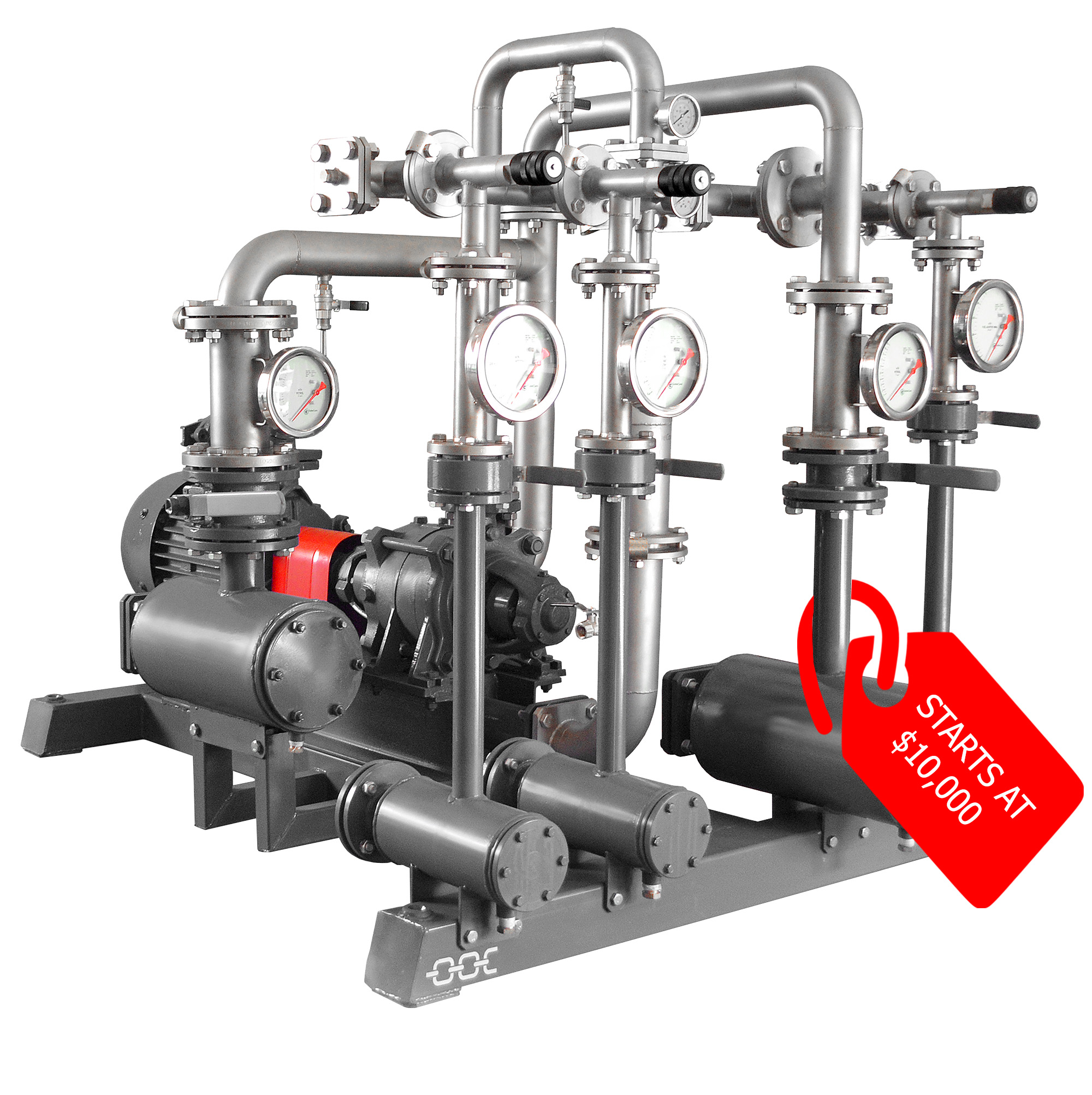

A common approach to antiseptic production is to use large tanks, where the components are mixed with agitators. GlobeCore has developed the USB blending machine to do away with the mixing tanks, save on equipment footprint, increase production rates, optimize the process and make it as efficient as modern technologies allow.

The USB plants can mix any number of ingredients, with the flow of each managed by a portioner. The use of ingredients is optimal: the plant takes only as much of the liquid component as is needed to make a high quality product. Blending occurs hydrodynamically, and takes seconds due to cavitation. No large mixing vessels are necessary. The product from the USB machines can be supplied directly to the bottling section.

Why choose USB mixing plants?

To sum up, the benefits that make the USB an excellent solution for making antiseptic solutions are as follows:

The price of the USB blending machines starts at $10,000. The investment to commission a USB machine may be higher than that for batch mixers. However, the return on investment comes quickly due to reduced operating costs and higher production capacity.

It is possible to install the blending machine on a skid or a trailer. The mobility of the machine makes it possible to produce antiseptic solutions in the same facilities where the ingredients are made.

Specifications of The Base Industrial Disinfectant Making Machine USB

| # |

Parameter |

Value |

| 1. |

Quantity of mixable liquids |

3 |

| 2. |

Minimum capacity at mixing of three components, m3/h (gpm) |

5 (22) |

| 3. |

Feeding liquid volume, m3/h (gpm): |

|

|

1-st component consumption |

3…4* (13-17,5) |

|

|

2-nd component consumption |

0,25…2,5 (1,1-11)* |

|

|

3-d component consumption |

0,1…1,0 (0,44-4,4)* |

|

| 4. |

Blender volume, m3 (gallon) |

0,004 (1)* |

| 5. |

Main liquid injection pressure, Mpa (Psi), max |

1,2…1,6 (174… 232) |

| 6. |

Mixture feeding height, m (in), max |

10 (390) |

| 7 |

Power consumption, kWt |

9 |

| 8. |

Maximum dimensions, mm (in) – length – width – height |

1600 (63) 500 (20) 1300 (51) |

| 9. |

Maximum weight, kg (lbs) |

260 (570) |

* Parameters are set according to formula.

To inquire about the USB machines or simply ask us a question, use the contact form below. Or write to email marketing@globecore.de.