GlobeCore Unit for Transformer Oil Reclamation

Benefits of GlobeCore Unit for Transformer Oil Reclamation

Older sobent based technology used a Fuller’s Earth sorbent material that was used only once and then was disposed of together with oil and harmful contaminants. The industry leading GlobeCore CMM-R equipment line utilizes the principle of cost efficient sorbent (Fullers Earth) reactivation and have a number of unique features:

- Extend transformers service life by 25 to 30 years;

- Reclaim the oil while the transformer is energized;

- Removes sludge, acids, water, and other contaminates from cellulose insulation;

- Reactivates the sorbent (Fuller’s Earth) automatically allowing the sorbent to stay in the unit for 2-3 years before replacement is needed;

- Oil reclamation and Fuller’s Earth reactivation is fully automatic;

- Disposal of sorbent is environmentally friendly and safe as Fuller’s Earth is free from oil and contaminants.

GlobeCore CMM-R Units for Transformer Oil Reclamation at Electricity Substation

The design of the CMM-R line of equipment includes automatic Fuller’s Earth reactivation for continuous reuse of the Fuller’s Earth materials. The Fuller’s Earth oil recycling system will allow oil processing to be carried out using one set of columns while the other set is re-activating the sorbent materials. Alternatively, oil processing or reactivation could be carried out in all columns giving the units a high degree of flexibility and cost effectiveness.

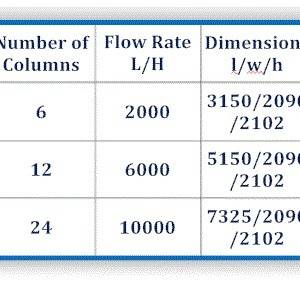

The GlobeCore CMM-R units comprise both degassing and oil reclamation systems. The design allows for stationary as well as mobile operation when mounted on a roadworthy trailer. The units vary in the number of Fullers Earth columns based on the model selected and the individual needs of the customer. GlobeCore CMM-R units are available with 6, 12 or 24 columns to meet different requirements and flow rates.

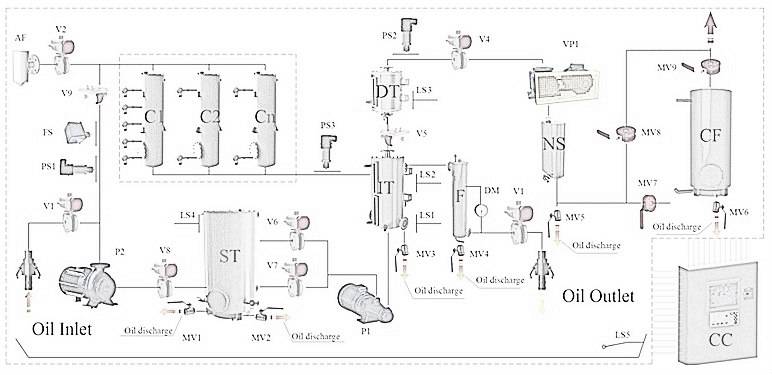

The CMM-R unit is fully controlled via a Supervisory Control and Data Acquisition unit (SCADA) system from a Laptop, positioned within the operators compartment and includes a touchscreen on the control panel. Valve operation is effected via a solenoid controlled compressed air system. Also included on the control system is a manual override mode. During operation, degassing and regeneration units are connected to the transformer. Oil is drawn into the degassing unit where it is heated to operational temperature and filtered. Oil is then pumped into the unit for reclamation and back to the degasser for the removal of moisture and dissolved gasses. The Figure below depicts the schematic arrangement of the CMM-R unit.

GlobeCore CMM R Plant Flow Diagram of Transformer Oil Reclamation

Key:

C1-Cn – Fuller’s Earth Column (number of columns depends on the capacity of the equipment), IT – Intermediate Tank, DT – Safety Tank (Oil Trap), NS – Noise Silencer, CF – Charcoal Filter, F – Filter, CC – Control Cabinet, ST – Oil Storage Tank, АF – Air Filter, PS1-PS3 – Pressure Transducer, VP1 – Vacuum Pump, P1 – P2 Oil Pumps,LS1 – LS4 – Level Sensors, LS5 – Leak Sensor, DM – Differential Pressure Gauge,V1 – V9 – Pneumatic Ball Valves, MV1 – MV9 – Manual Control Valve