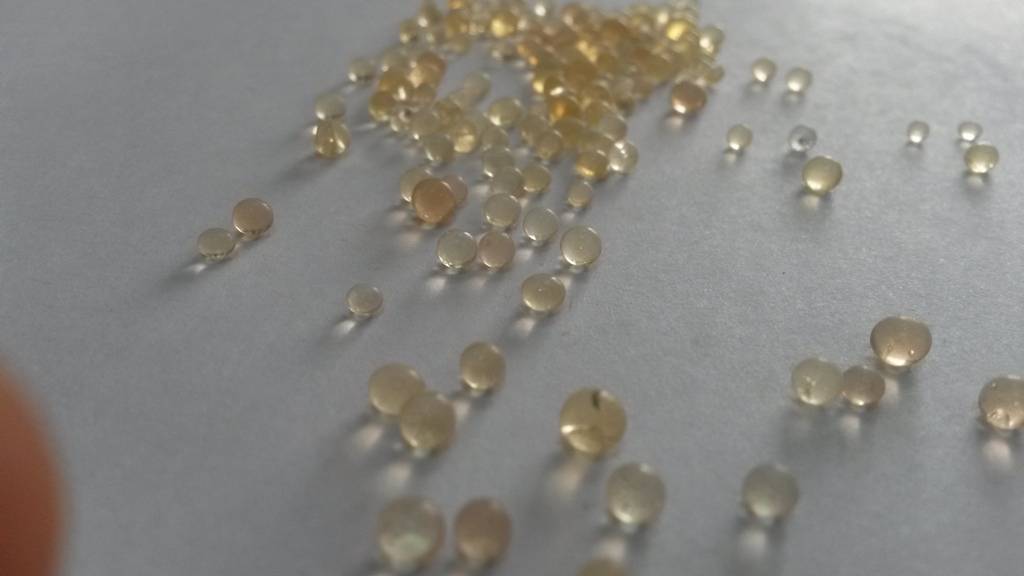

Regeneration – is the process of restoring silica gel performance after it cleaned and dried some products (e.g., mineral oils).

Depending on the volume of silica gel, its regeneration can be carried out in a chemical laboratory, in a household environment and by industrial methods.

Regeneration process includes three stages:

- cleaning of silica gel (depends on the initial state of the sorbent);

- desorption – removal of previously absorbed substances;

- cooling of silica gel.

One of the most efficient industrial processes for the recovery of silica is drying it by blowing dry air. In laboratory conditions – regeneration of the sorbent is carried out by heating it in an oven to 150-170ºS for 3-4 hours.

After household use, the properties of silica gel can be restored by drying it on a radiator or in an oven. It is necessary to maintain a temperature no higher than 170 ° C.

GlobeCore BRPS installation is used for industrial recovery of silica gels after it purification of mineral oil. This equipment washes sorbents with superheated steam and removes adsorbed substances by thermal desorption with special electrical heaters.

Advantages of BRPS stations:

- Restore operating parameters of silica, and other sorbents: zeolites;

- Prolong life of silica gel;

- Mobile and easy to operate;

- Direct connection to cartridges filled with silica gel.

BRPS installation can operate in steam mode, vacuum drying and cooling.

GlobeCore processes of regeneration of sorbents, extend the life of the various adsorbents (silica gels, zeolites, bleaching earth, etc.), saving money and reducing impact on the environment.