Mobile Transformer Oil Purification Plants CMM 4

Cmm equipment can Purification Plants

- Removes Water from 100 ppm down to 10 ppm and from 50 ppm to 5 ppm in a single pass (ASTM method D-1533)

- Reduces Gas content from fully saturated with air (10 to 12% by volume) to less than 0.1% (ASTM D-2945)

- Removes Particulate Matter to 5 microns as standard or down to 0.3 micron (optional)

- Improves dielectric strength up to 75 kV

The GlobeCore Oil Purification Plant CMM 4 m3/h is designed for removal of solid particles and free and dissolved water from transformer oil, lubricating oil, turbine oil and compressor oil.

The GlobeCore CMM 4 Oil Purification Plant is able to process oil on a “tank to tank” basis or directly on energized or de-energized transformers. Trolley or trailer mounted, semi-automated, fully automated (PLC controlled) and explosion proof versions of this unit are available. Optional equipment includes moisture probes, flow meter with totalizer, and 0.3 micron fine oil filter.

|

№ |

Mobile Oil Purification Plants CMM 4 Specifications | Value |

|

1 |

Production capacity, m3/h: | |

| – thermo-vacuum mode | 4 | |

| – heating and filtration mode | 7 | |

|

2 |

Treated oil parameters: | |

| – water content, ppm, maximum | 3 | |

|

3 |

Nominal filtration rate, mkm | 0.3… 5 |

|

4 |

Outlet oil temperature, °С | 60 |

|

5 |

Oil Pressure on outlet, Mpa, minimum | 0.15 |

|

6 |

Heater power consumption,kW, maximum | 36 |

|

7 |

Total Power Consumption, kW | 42 |

|

8 |

Electrical outlet parameters 50/60 Hz, V | 380/220 |

|

9 |

Dimensions, mm, maximum length/width/height, mm | 1625/1225/1600 |

|

10 |

Weight, kg, maximum | 870 |

GLOBECORE OIL PURIFICATION PLANTS CMM 4; COMPONENT DESCRIPTION:

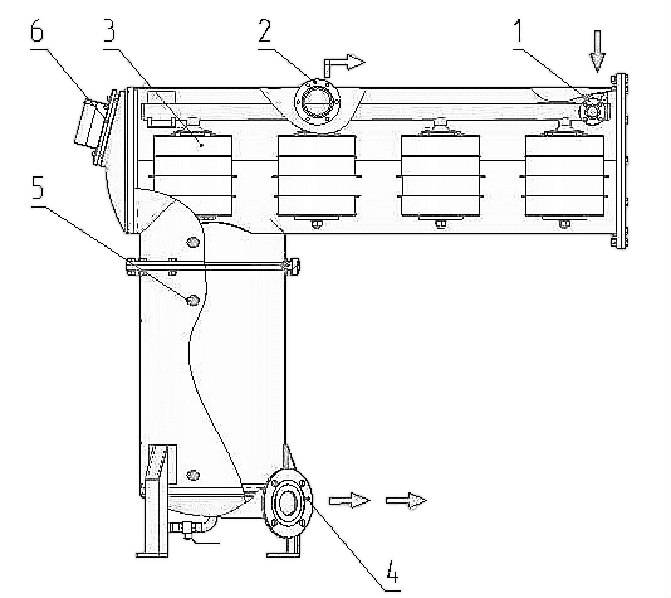

Vacuum Chamber

1-Oil Inlet ; 2-Vacuum Pump Connection; 3-Coalescer; 4-Oil Outlet; 5-Level Sensor; 6-Sight Glass

Vacuum Chamber Vessels and all internal parts are made of carbon steel and feature Coalescers, Sight Glass, Oil Level Controller, Foam Sensor and Vacuum Gauge. The Vacuum Chamber’s rigid design makes it suitable for stationary and cmm mobile installation. Appropriate flexible connections are provided to the outlet and inlet pumps to minimize negative effect of vibration during plant operation and transportation.

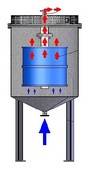

Coalescers – The unit has four (4) built-in coalescers and are provided for the maximum exposure of oil to the effect of vacuum. Due to the reduced pressure, dissolved water and gases are vaporized through the secondary chamber and filtered into the atmosphere.

Secondary Chamber (Oil Trap) – serves as safety feature to ensure that no oil is pulled into the vacuum pump.

Vacuum Gauge – is provided to monitor Vacuum level in the Vacuum Chamber.

Oil Level Controller – consists of three capacitive probes provided to maintain required level of oil in the Vacuum Chamber.

Foam Sensor – rarely, under certain conditions oil foaming may develop. When the Optical Sensor, installed in the Vacuum Chamber, detects a high level of foam it will actuate a Solenoid Operated Valve to reduce vacuum and foam level.

Vacuum ports – vacuum connection is provided to pull vacuum on transformer.

Vacuum System

Vacuum System

Rotary Vane Positive Displacement Pump

Pumping Speed 100 m3/h

Ultimate pressure 0.5 mbar

Oil Heater

Oil Heater

36 kW Oil Heater has two stage heating facility with 18 kW of power each. A low watt density heating elements (1.2 W/cm2) are used to prevent heat degradation of oil. The heater is controlled be electronic temperature controller.

Inlet and Outlet Oil Pumps

Inlet and Outlet Oil Pumps

“Calpeda” Centrifugal pumps with power consumption of 4 kW and capacity of 12m3/h are utilized to draw oil in and out of the vacuum system. All electric motors are protected by overloads.

Instrumentation and Controls

Instrumentation and Controls

Manometers – are installed to monitor the state of Coarse and Fine Filters.

Temperature controller – takes an input from a temperature sensor and is connected to a control element of the heater.

Filters

Filters

A Mesh Strainer is provided to remove large particles that could cause damage to the Inlet Pump. A Coarse Filter for particles larger than 5 microns is installed at the entry port to the Vacuum Chamber. Oil then receives its final treatment by passing through the Fine Filter designed to remove 99.9% of particles larger than 2 microns or with an optional 1 micron capability.

Measuring and control parameters are pre-set by the manufacturer.

Measuring and control parameters are pre-set by the manufacturer.

Power and Heating Indicators and Switches, Inlet and Outlet Oil Pumps Switches– are located on the control panel.

Emergency Stop Button – is provided for safe shut down of the plant in case of emergency.

Alarms and Interlocks

GlobeCore CMM plants feature the following safety devises that ensure simple and reliable operation and will safely shut down the system in case of any alarm situation:

High Level Alarm – will alert plant’s operator by activating sound and light alarms and shut down the system safely should high level of oil persist.

Low Level Alarm – interlocked with the inlet pump low level alarm will safely shut down the plant in case of insufficient oil level.

Flow Sensor – only activates the Heater when oil flow is detected.

Foam Sensor – prevents excessive foaming

Overloads – all motors are protected by overload shutdown devices.

Alarms – sound and light alarm with silence button will alert plant’s operator of any emergency situations.

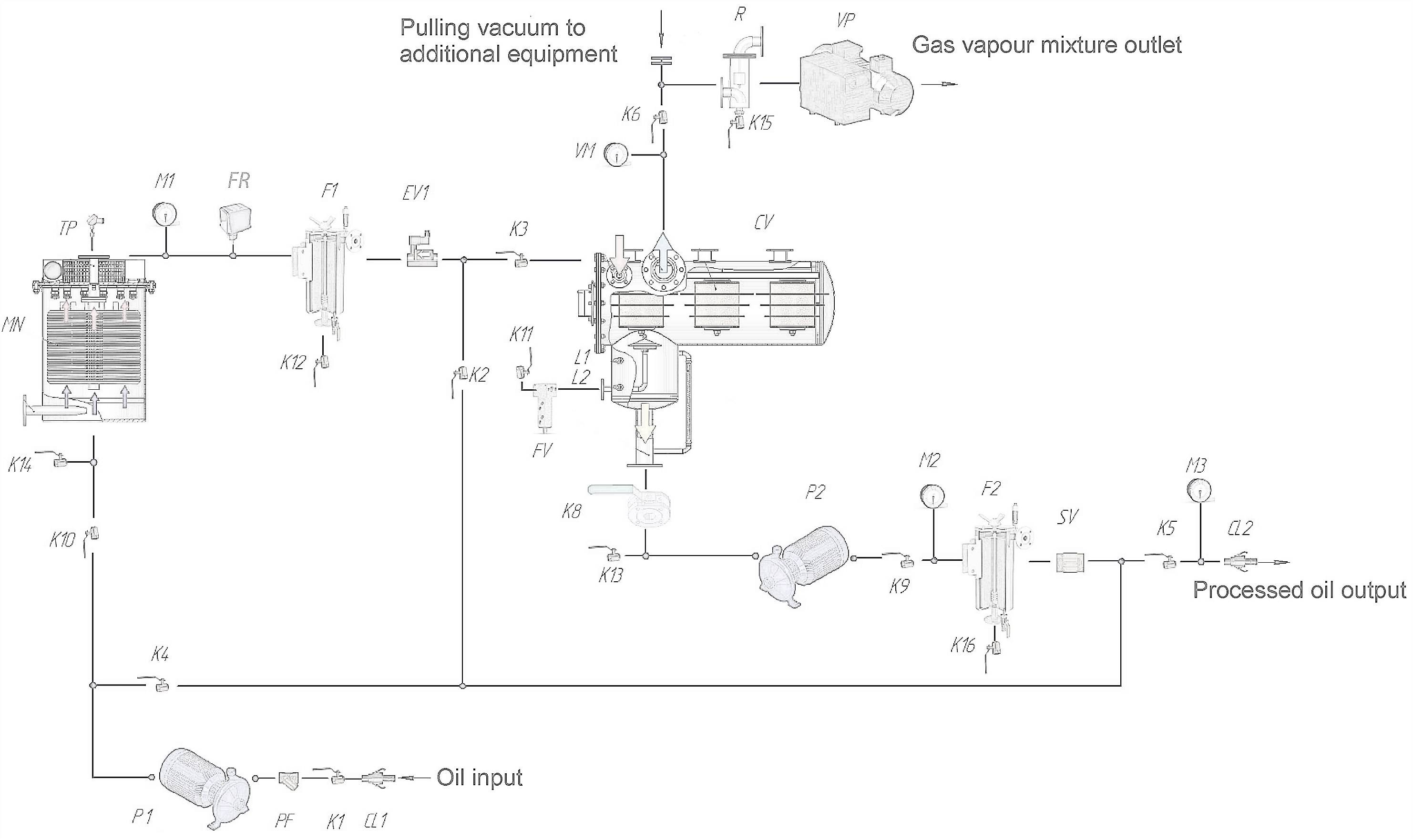

GlobeCore Oil Purification PlantS CMM 4 Flow Diagram

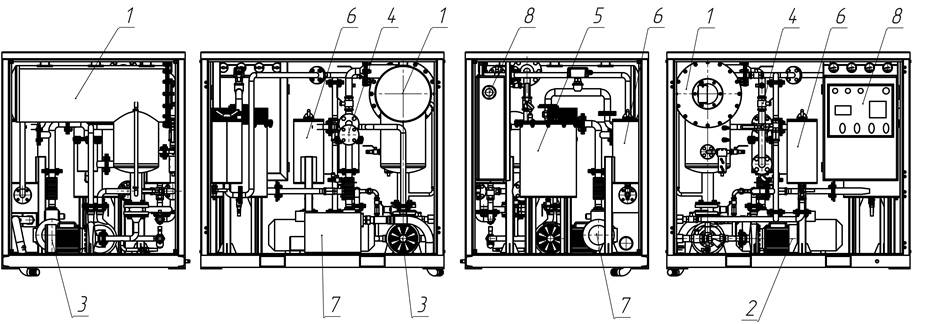

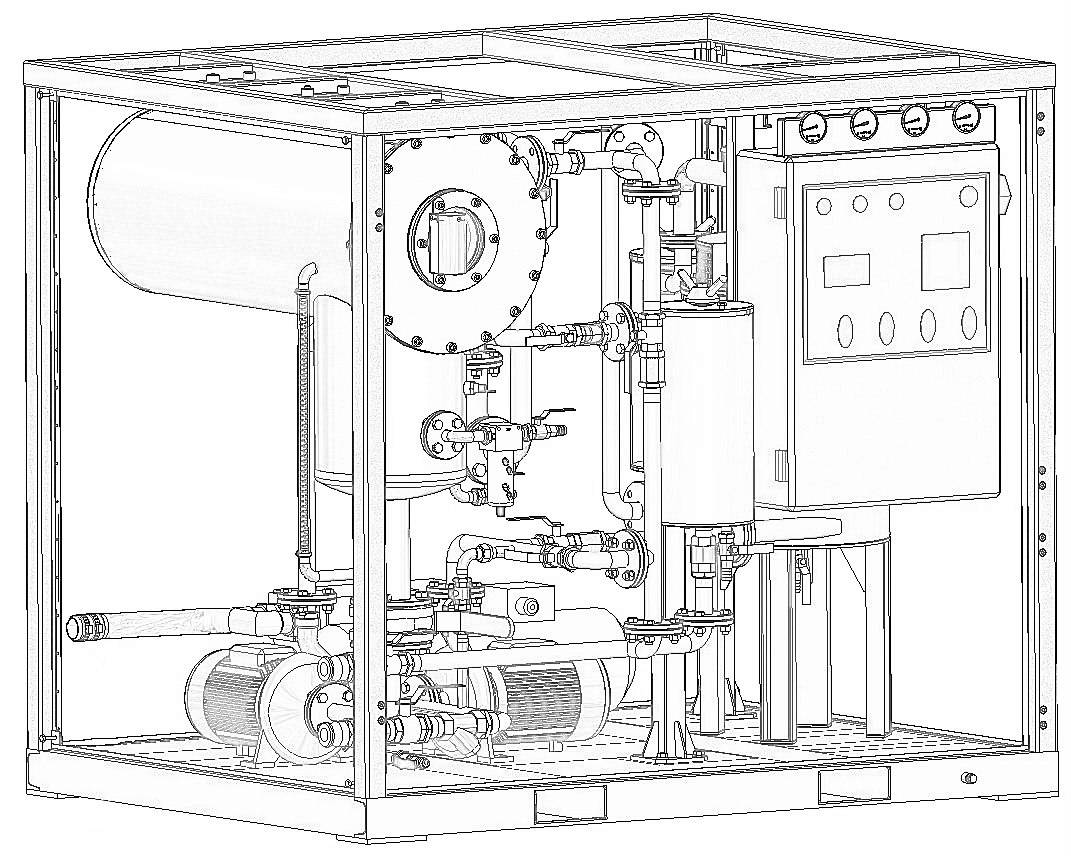

OIL PURIFICATION PLANTS 3D DIAGRAM

Identification Key : vacuum column 1, oil inlet pump 2, oil outlet pump 3, pipeline system with stop and control valves 4, oil heater 5,fine filt er 6, vacuum pump 7, control panel 8.

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT

GlobeCore Fuller’s Earth Сartridges (ZP-260)

GlobeCore Fuller’s Earth systems are specially engineered to remove soluble contaminants such as acids, waxes, gums, resins, carbon residues and colloidal particles from transformer oil. They are designed for oil polishing after purification. For large quantities of oil GlobeCore’s regeneration system is recommended.

Moisture Probe

Moisture Probe

The transmitter provides on-line transformer oil measurement of both the moisture content and the temperature. The unit comes complete with a display showing the level of moisture in a “ppm” readout.

Typical Oil Parameters after Treatment with the GlobeCore Process Fuller’s Earth filter system

| Parameter | Test Method | Before Reclamation | After Reclamation |

| Appearance | Visual | Cloudy Brown | Clear and transparent |

| Acid Number, mg KOH/g | IEC 296; ASTM D-664 | 0.63 | 0.01 |

| Corrosive Sulphur | ISO 5662;ASTM D-1275 | Present | Absent |

| Tangent delta at 90°C | IEC 247; ASTM D-924 | 4.0 | 0.001 |

| Oxidation Stability, mg KOH/g | IEC 1125А;IEC 1125B; IP-307 | – | 0.2 |

| Surface Tension at 25°C, mN/m | ISO 6295;ASTM D-2285 | 22 | 45 |

PORTABILITY OPTIONS

PORTABILITY OPTIONS

The GlobeCore CMM Mobile Oil Purification Plants is mounted on a durable, roadworthy trailer with torsion suspension and “Off Road” capabilities. It has the appropriate reflectors and tail/brake lights to make the trailer “Street Legal” in all jurisdictions world wide and is capable of being towed at speeds of up to 100km/h/60 M.P.H. The system components and controls are enclosed with water proof metal covers (protection class IP45) and the trailer has a four (4) post leveling and stabilizing system to secure the plant in a stationary position while in operation. Maximum noise level emitted by the CMM 4 Unit is below 80 db.

GlobeCore Worldwide Sales